Solution for Air Inlet / Weather Hoods

What level of protection do you believe a weather hood gives your filter system, and what impact are the hoods having on the airflow within the housing?

Veotec, a subsidiary of the Wozair Group, believe that these are compromises that you don’t need to make, our vertical louvres provide unsurpassed levels of water removal, down to 2µm water droplets. Weather hoods have no efficiency against airborne water droplets, they are only effective against falling rain.

Additionally, due to the continuous nature of a vane separator, compared to the segmented nature of weather hoods, the airflow into the filter house is much less turbulent and the velocities are much more even.

Traditionally gas turbine filter houses are fitted with weather hoods for the first stage of protection against the weather. Primarily their function is to remove bulk water from rain fall and snow protection.

However, we believe there is a better more economical solution.

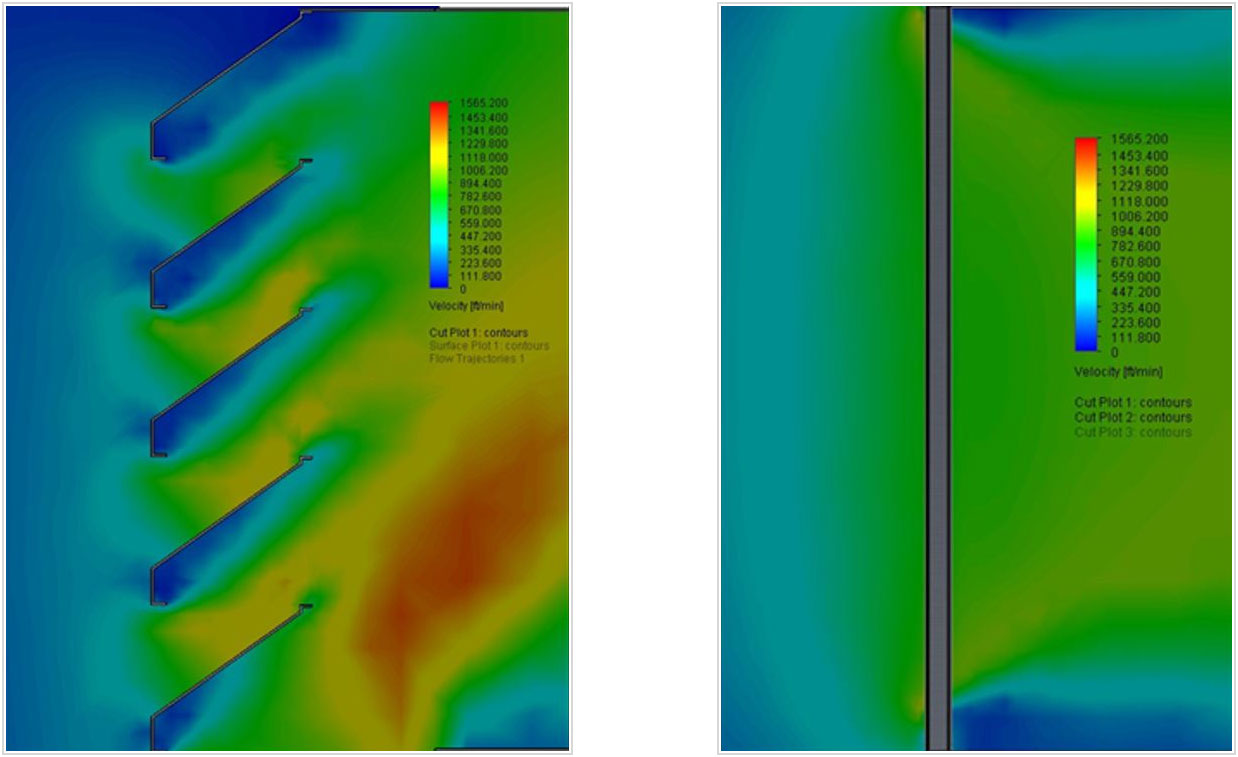

Flow through traditional weather louvres / Flow through Veotec vertical louvres

These CFD images show incoming air velocity for traditional weather hoods and vertical louvres/inertial vane separator using identical air volume and duct dimensions.

This comparison clearly shows traditional weather hoods have radical fluctuations in velocity compared to vertical louvers/inertial vane separators.

The highest velocity for weather hoods is typically observed nearest to the rear of the hoods and biased across the inlet to the lowest hoods. This means the face area of the air intake does not get an even distribution of air flow resulting in the subsequent increased likelihood of water ingress and a varied distribution of air within the filter house across all stages of filtrations as certain sections become more heavily loaded than others.

A common solution that is deployed to combat the aforementioned affects weather hoods is the installation of drift eliminator panels to remove some of the droplets that would normally bypass the weather hoods. The efficiency of water droplet removal is linked to velocity therefore in a similar fashion to those reasons stated above, the majority of drift eliminator panels will have minimal effectiveness. Such drift eliminator panels shall also bare a significant additional pressure loss restriction to the system.

By installing Veotec’s vertical louvres/inertial vane separators in place of weather hoods the air velocity and distribution is uniform across the full face of the filter house giving predictable performance against water ingress. In independent testing this equipment has been shown to remove 97% of 2 µm water particles and 100% of 5 µm water particles with a pressure loss of only 20Pa at 3.0 m/sec velocity and even greater performance at higher velocities.

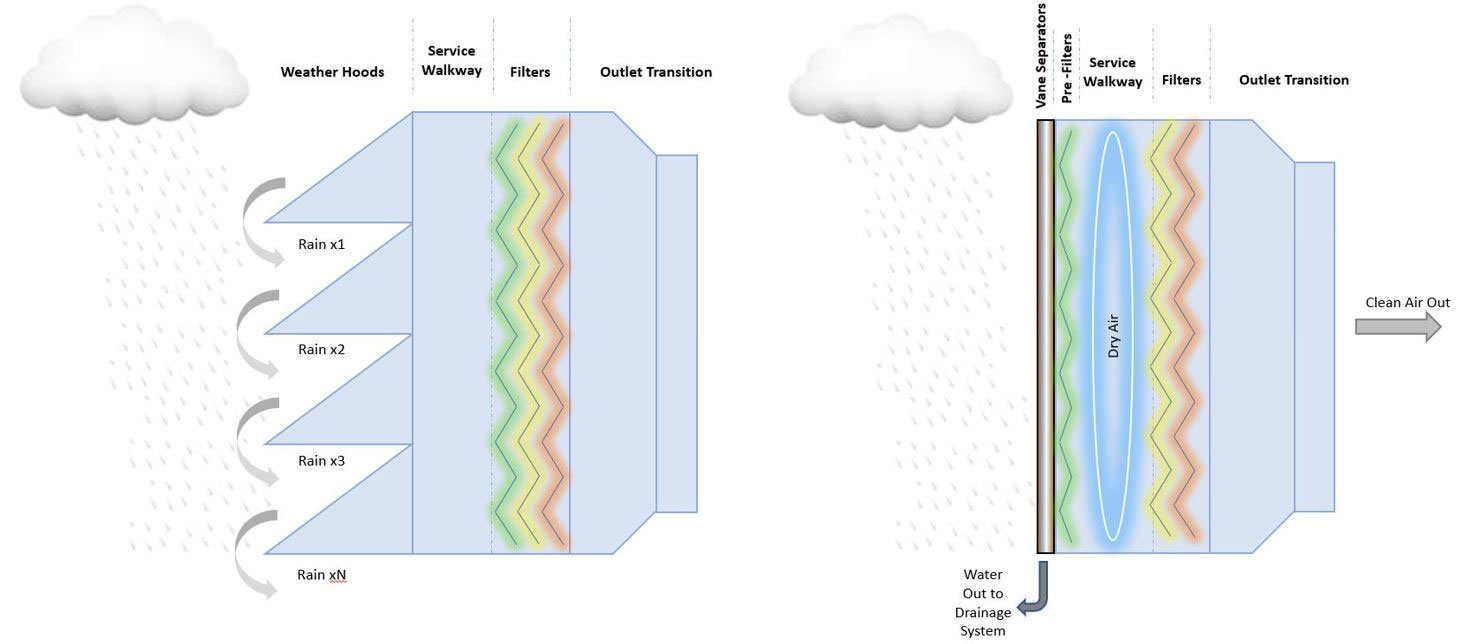

Rain and traditional weather hoods / Rain and Veotec vertical louvers/inertial separators

Furthermore, filter houses with fitted with weather hoods lacking in sufficient drainage facilities are often subject to an inherent problem whereby rain cascades down the front of the hoods. The collected water generally drops from one hood down to the next hood multiplying the water from hood to hood down the face of the inlet. A simple rain shower quickly becomes a waterfall across the hoods. The first few rows of hoods may resist ingress however the lower sections of the intake shall eventually can become overwhelmed by the volume of water leading to further ingress into the filter house often to the detriment of the pre-filters leading to increased maintenance as the bottom rows of filters quickly get saturated.

Filters exhibit a spike in restriction prematurely, leading to reduced filter efficiency, shortened filter service life and contamination getting washed through the filters.

Due to the design of the vertical louvres/inertial vane separators, the amount of water that can be removed is very high and does not vary across the face area of the inlet. In independent test results the water handling capacity of this equipment was 36 litres (9.45 galls) per minute per square metre of product.

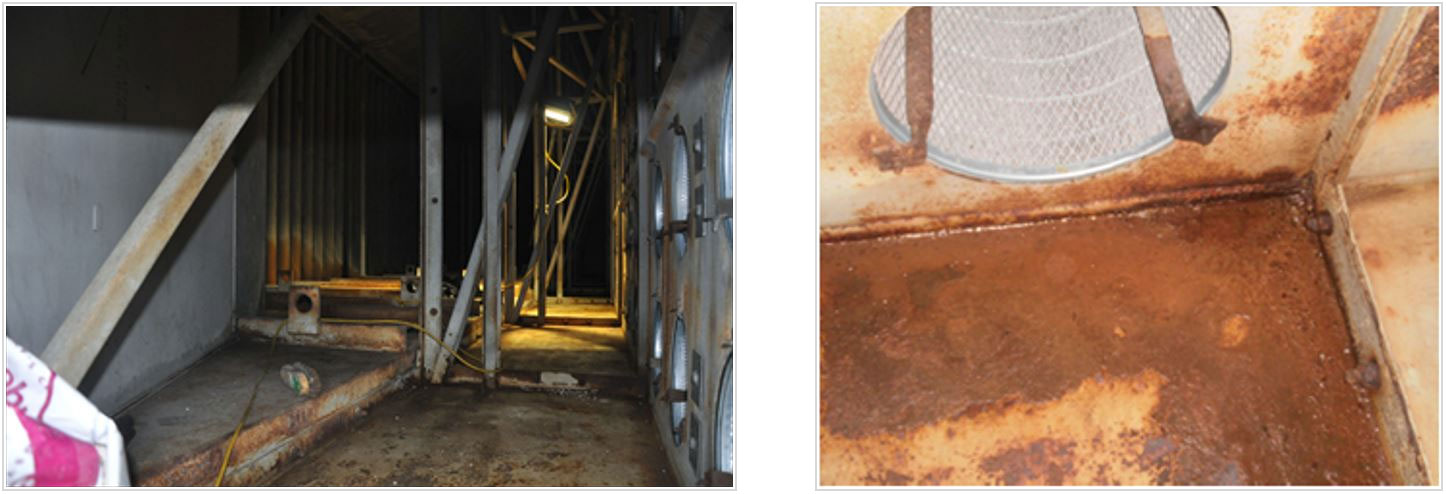

Photographs from inside a typical filter house fitted with traditional filter hoods

Photographs from inside a typical filter house 12 months after having vertical louvres/inertial vane separators fitted

The water ingress and air velocity variations can also cause several problems for the air filters.

Filters are tested in a controlled laboratory setting with relatively uniform velocity conditions and generally stable humidity. These filters are given performance ratings. Those standardized ratings help end users select appropriate performance characteristics to suit their needs. Unfortunately, many filters will experience reduced efficiency and lower dust loading capacity at higher velocities. A F9 filter at 4 m/s (787 ft./min) may drop a grade or two at 5 m/s (984 ft./min.)

Dry filters generally maintain efficiency as reported – Standardized tests classify dry filters in a dry laboratory environment with dry dusts. Saturating filters will change the performance.

Filters capture and remove particulate from the air. Filters eventually load and either need cleaning or replacement. Some of the contaminants captured on the filters are water soluble. The addition of water or moisture into an installation converts some particles into a solution which is detrimental to the performance of the filtration and or subsequent systems and processes, such as saline solutions which can cause corrosion. Some soluble solutions can seep through most air filters like coffee flows through a coffee filter. The contaminated solution migrates through the filter from the dirty air side to the clean air side where it can dry out and become airborne later. Carrying the contamination into the turbine or other equipment downstream of the filters.

Some of the contaminants captured on the filters absorb moisture and swell up like a sponge. Some filters use hydrophilic fibres that also absorb water. These hydrophilic particles and fibres grow and blind off the filter media when wet causing the restriction to increase. The air simply must work harder to get past the larger particles. The level of dust loading and the amount of precipitation bypassing the hoods will impact the intensity of the restriction spikes and the time required to recover after a precipitation event.

Wet particles and fibres may also contribute to premature filter media breakdown in freezing environments. Hydrophilic particles hold moisture next to the filter fibres. The moisture then expands during freeze events causing microscopic ruptures throughout the filter surface. Repeated wetting and freezing events will result in performance degradation.

End of filter life is normally observed as increasing frequency and intensity of restriction and precipitation induced restriction spikes. Dry filters will perform better and last longer.

For more information please contact us.

November 2019

Back to news